Circle Machine Knitted Fabric has become an essential component in the fabric production industry, renowned for its versatility and efficiency. This innovative fabric is manufactured using circular knitting machines, which facilitate the creation of seamless tubes of fabric, greatly enhancing the efficiency of the knitting process. The resulting material is characterized by its soft texture, elasticity, and ability to drape well, making it an ideal choice for a wide range of applications including clothing, home textiles, and industrial uses.

Understanding how Circle Machine Knitted Fabric is made is crucial for those involved in textile manufacturing, design, or in the fashion industry. This process begins with selecting the right type of yarn, which can range from cotton and wool to synthetic fibers, depending on the desired qualities of the final product. The circular knitting machines then turn these yarns into fabric through a continuous loop process that not only speeds up production but also reduces waste. As we delve deeper into this topic, we will explore both the technical aspects of the knitting process and the various advantages that Circle Machine Knitted Fabric offers to manufacturers and consumers alike.

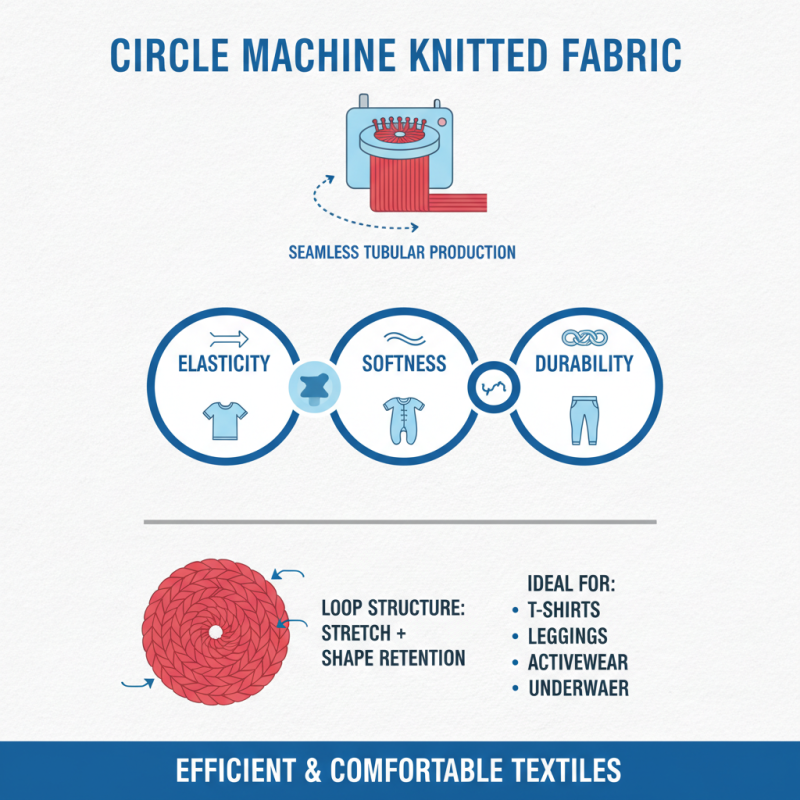

Circle machine knitted fabric refers to textiles produced using circular knitting machines, which create seamless tubes of fabric. This method is particularly popular due to its efficiency and the unique characteristics of the resulting material. Circle machine knitted fabrics are known for their elasticity, softness, and durability, making them ideal for garments like t-shirts, leggings, and other close-fitting clothing items. The loop structure allows the fabric to stretch without losing its shape, providing comfort and flexibility.

When selecting circle machine knitted fabric, consider its weight and texture. Fabrics can range from lightweight cotton blends to heavier jerseys, influencing the drape and use of the material. Additionally, look for options that have been pre-shrunk to minimize any changes after washing.

**Tips:** Always check the labeled care instructions for circle machine knitted fabrics, as improper washing can affect their longevity and appearance. For optimal comfort, choose fabrics with a higher percentage of natural fibers to allow breathability and reduce static.

The historical development of circle knitting technology can be traced back to the 19th century when mechanized knitting machines began to emerge. Early innovations in this field aimed to increase efficiency in fabric production, significantly reducing the labor involved in hand-knitting. The circular knitting machine, which allowed for the continuous production of fabric in tubular form, marked a turning point. This technology enabled manufacturers to produce socks, hosiery, and other seamless garments, thus meeting the growing demand for knitted textiles in the fashion industry.

As the 20th century progressed, advancements in materials and automation further transformed circle knitting. The introduction of synthetic fibers expanded the versatility of knitted fabrics, while computerized machines improved precision and output speed. These developments laid the groundwork for modern circle knitting, which now plays a crucial role in producing a wide array of garments and technical textiles. The evolution of circle knitting technology not only revolutionized manufacturing processes but also influenced design possibilities, allowing for intricate patterns and diverse fabric properties that cater to contemporary market needs.

This bar chart illustrates the historical development of circle knitting technology, showing the increase in the number of knitting machines from the 1830s to the 2020s. The advancements in technology have significantly contributed to the growth in production capacity and efficiency in the textile industry.

Circle knitting machines are specialized tools designed for the efficient production of circular knitted fabrics. These machines operate by using a series of needles arranged in a circular configuration, allowing them to create seamless tubes of fabric. The process begins with feeding yarn into the machine, where it is drawn into the needles. As the machine rotates, the needles engage with the yarn to form loops, creating a continuous fabric structure. This method allows for high-speed production and consistent quality in the finished product.

The operation of circle knitting machines is characterized by several key components, including the needle bed, sinkers, and the take-down system. The needle bed holds the needles in place, while sinkers help to secure the loops of yarn as they are formed. The take-down system plays an important role in controlling the fabric's tension and delivering the finished product for further processing. Advanced models of circle knitting machines may also incorporate computerized controls for precise adjustments in stitch patterns and fabric width, making them versatile tools in the textile industry.

Circle machine knitting is a widely used process for producing knitted fabrics, and the choice of materials plays a crucial role in determining the quality of the final product. Commonly used materials in circle machine knitting include cotton, polyester, wool, and nylon, each influencing the fabric's characteristics uniquely.

According to a report by Textile World, cotton offers breathability and comfort, making it ideal for casual wear, while polyester is favored for its durability and resistance to wrinkles, moisture, and fading.

The impact of these materials extends beyond their physical properties; they also affect the technical aspects of the knitting process. The elasticity and strength of the yarn can influence the fabric's stretchability and recovery, essential qualities in activewear and sports fabrics. Industry research indicates that using high-quality synthetic fibers can enhance the longevity of the fabric, reducing the need for frequent replacements. Conversely, lower-quality materials may lead to pilling, fading, and reduced lifespan of the garments, as highlighted in the 2022 Global Textile Report. Thus, selecting the right materials is pivotal not only for the aesthetic appeal of the knitted fabric but also for its performance and durability.

Circle machine knitted fabrics are increasingly gaining traction across various industries due to their flexibility and unique properties. One major application is in the fashion and apparel sector, where designers favor these fabrics for their ability to stretch while maintaining shape. This quality makes them ideal for items such as activewear, sports bras, and fitted garments, providing both comfort and style. Furthermore, the versatility of circle machine knitting allows for a wide range of textures and patterns, appealing to consumers seeking individuality in their clothing choices.

In addition to the fashion industry, circle machine knitted fabrics find utility in home textiles, such as blankets, curtains, and upholstery. The durable nature of these fabrics, along with their aesthetic appeal, positions them well in the ever-evolving home décor market. Market trends indicate a growing demand for sustainable and eco-friendly materials, and manufacturers are responding by incorporating organic fibers into their knitted fabrics. This shift not only meets consumer preferences but also aligns with environmental standards, reinforcing the position of circle machine knitted fabrics as a significant player in both fashion and home textile markets.